Hello, welcome to Muyao Technology

- muyaokeji@163.com

- 15822855000

Contact: 15822855000

022-26971751

400 1898 959

Company Address: Tsing Hua University Park Headquarters, Beichen District, Tianjin

Automatic fire extinguishing equipmentSelection of specifications

Answer: The extinguishing dose of the product corresponds to a certain sealed environment. According to the different sealing conditions of the cabinet, the required dose will be adjusted. In the actual application process, it is designed to be excessive. Although the measured extinguishing agent concentration can reach 2.7% to extinguish the fire, we generally design 130g/m³ in accordance with the gas fire extinguishing specification, so that it is safe and reliable and there are specifications to refer to.

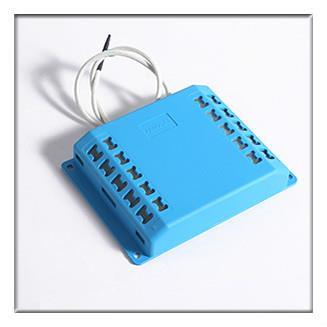

ZMM-10W (20A) (applicable space is about 0-0.06m³ independent relatively sealed environment) ZMM-20W (applicable space is about 0-0.15m³ independent relatively sealed environment)

ZMM-40W(20B) (applicable space is about 0-0.3m³ independent relatively sealed environment) ZMM-80W(20C) (applicable space is about 0-0.6m³ independent relatively sealed environment)

Independent space means that there is no other independent and isolated space in this space; relative sealing means that the tightness is more than 80% and all the ventilation parts are not concentrated in a certain position.

Packaging and customization of automatic fire extinguishing equipment?

Answer: The packaging of automatic fire extinguishing equipment is divided into company standard packaging and customer special packaging; product label, shape, color, starting method, data communication module can be customized (a certain minimum order quantity is required).

Matters concerning the use of automatic fire extinguishing equipment

Are there any residues in the product after the reaction? Can it be cleaned up?

Answer: After the product is reacted, there is a complete shell remaining. Due to the high degree of heat resistance of the shell, the denaturation is small. It can be removed directly after the temperature is cooled (such as using 3M glue, vinegar, alcohol, wind oil, toilet water Remove after wiping). The outer shell of the temperature sensing wire will be brittle, leaving a white fragile wire cover. Use a rag or a vacuum cleaner to gently suck the residue away. After the reaction of the built-in agent is completed, there may be a little black powder (but a filter is installed inside the product to seal the powder inside the shell).

Relying on scienceInnovation and Technologychange life

查看更多 >

Tianjin Muyao Technology Development Co., Ltd. is a company specializing in R&D, production, sales and brand strategic marketing services for fire protection products. The company cooperates closely with the Weapon Group and a number of well-known universities and research institutes. The core research field is the design and development of small space fire protection systems and products.查看更多 >

Your Name:

E-mail:

Phone:

Content: